There has been increasing consumer concern over the use of ‘chemicals’ in everyday products, as a consequence, there has been a surge in the number of do-it-yourself or homemade products being publicized on-line. Sunscreens are no exception to the DIY craze, but are these products all they’re cracked up to be? In short, the answer is no, they most certainly are not!

The chemicals argument

The principal reason behind the desire for homemade skin care products relates to concerns over the chemicals used in store bought products. Unfortunately, the concerns are not founded on fact, homemade products contain chemicals, although the chemicals may be natural, this does not miraculously make them any safer than mineral, synthetic or naturally derived alternatives, in fact, the opposite is often the case.

Naturally sources ingredients are complex mixtures of chemicals and can contain hundreds of discreet chemicals, those available to those at home are often food grade in nature and unrefined and not suitable for use on the skin. Some of the most toxic chemicals known are found in nature, a few examples include Ricin and Alfatoxin, most common pesticides are also natural.

Synthetic chemicals are also found in plants where they are unable to be extracted at meaningful quantities, nature identical synthetic chemicals will be manufactured. Synthetic chemicals often sound harmful merely as a consequence of their unpronounceable names, however, have been refined and considerably more pure than naturally sourced ingredients.

Sunscreens, more than just a number

When you buy an off the shelf sunscreen, you are buying assurances. Commercial sunscreens have been formulated by highly experienced and tertiary qualified development chemists and they have been designed and stringently tested to comply with regulatory standards.

In Australia, regulatory standard refers to an Australian & New Zealand Standard (AS/NZS 2604:2012) and the Sun Protection Factor (SPF) has been certified. For a high SPF, water resistant sunscreen for full body use, it will also comply with the Australian regulatory guidelines for sunscreens (ARGS). Further to this, the ingredients used are approved and deemed safe for use by the Therapeutic Goods Administration (TGA), and manufactured following principles of Good Manufacturing Practice (GMP). There is also a high likelihood that the product has been dermatologically tested to confirm skin compatibility and qualify as non-irritating and non-sensitizing (low allergenic).

The evidence

Below is the absorbance profile of a store bought SPF50+ sunscreen (tested to AS/NZS 2604:2012) prepared using roughly 26% synthetic UV filters as compared to a DIY sunscreen prepared using ingredients and instructions detailed on-line, containing roughly 26% mineral UV filter (zinc oxide):

As can be seen, the absorbance for the DIY sunscreen (white line) is incredibly low as compared to the store bought sunscreen (black line). Using software to interpret the absorbance profile, the estimated SPF for the DIY sunscreen is SPF5, 10 times less than the store bought sunscreen which has been certified as SPF50+.

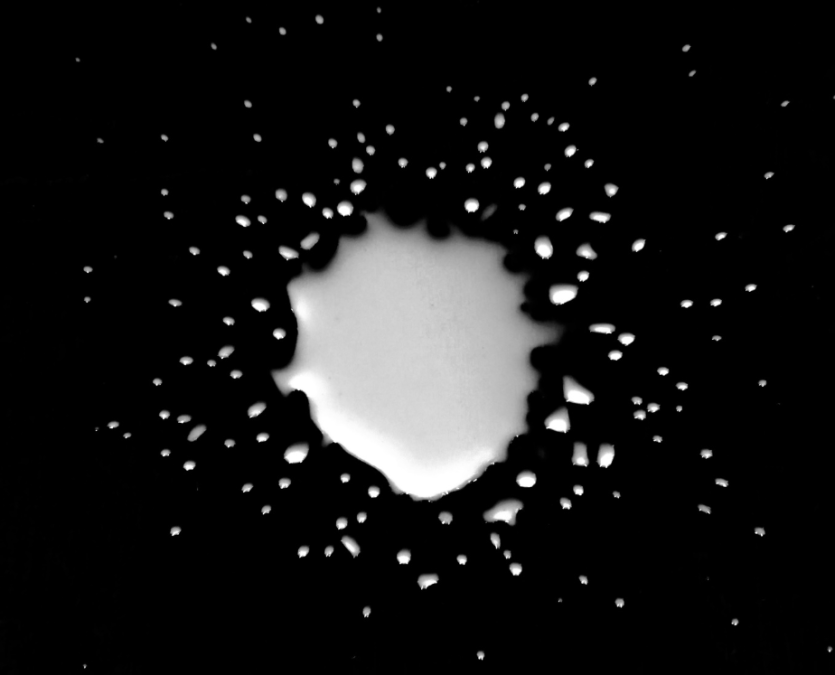

Below is a similar comparison using store bought Invisible Zinc brand SPF50+ that contains ~26% zinc oxide which is more comparable to the DIY sunscreen with respect to active ingredient used, again, the DIY sunscreen has incredibly low absorbance in comparison.

What causes this difference?

The key differences between the DIY and store bought sunscreen are; zinc oxide, the other ingredients and the process used to manufacture the product.

The zinc oxide suspected to be used in Invisible Zinc SPF50+ sunscreens is a highly specialized UV filter grade zinc oxide that is only available to industry, these grades are purposely engineered to absorb more UVB light (sunburn protection) with greater transparency in the visible light region so as not to appear white on skin. There is likelihood that the zinc oxide is also used in combination with synthetic, pseudo UV filters that also absorb UVB light to achieve a high level of performance, these ingredients can include Butyl Octyl Salicylate, Polycrylene or Ethylhexyl Methoxycrylene.

Other ingredients helping to support the active ingredients achieve maximum UV light absorbance include those that help form a uniform film over the skin, minimizing the potential for unprotected skin, along with those that provide water resistance so the protection remains after swimming or exercise.

The process used to manufacture the products will also be vastly different, commercial sunscreens will often be produced with high energy mixers (think of a Nutribullet, but far more advanced and costing tens of thousands of dollars) that break up agglomerates of zinc oxide that would otherwise provide very little protection and distributing them evenly throughout the product, maximizing every possible ounce of protection from the UV filters.

Sunscreens are not art, they’re science

Making sunscreen at home may sound crafty, however, the end result delivers very questionable levels of protection from poor quality ingredients and techniques and ultimately have not been tested to confirm effectiveness, unlike those purchased from a retailer or pharmacy.

Your skin is no place to perform experiments that impact your health. The risk of sunburn as a result of not properly protecting your skin is absolute, the risk of skin cancer from repeated exposure is incredibly high, although will go unnoticed for many years. The risk of harm from synthetic chemicals is low, if a product causes an allergic reaction however, then its use should be discontinued and an alternative store bought product should be found.

Those that consider making their own sunscreen should understand they are attempting to make what can be considered an anti-cancer drug. Would they consider making a vaccine or a heart disease medication if the materials were more accessible?

References